Measurement of dust levels

Monitoring of a worker’s health is legally required when the hazard has the potential to exceed exposure limits or the level of risk from the hazard varies.

OHSA has conducted 100’s of airborne contaminant surveys in lots of different workplaces including:

- Coal Mines

- Metalliferous Mines

- Quarries

- Sawmills

- Foundries and Smelters

- Manufacturing Facilities

- Cement Plants

- Construction Sites

- Road and Rail Projects

Section 49 of the Work Health and Safety Regulation 2011 states that a person conducting a business or undertaking at a workplace must ensure that no person at the workplace is exposed to a substance or mixture in an airborne concentration that exceeds the exposure standard for the substance or mixture.

Businesses must have a documented way of managing dust and a strict monitoring program to ensure dust exposure is kept to an acceptable level and statutory exposure standards are met. Part of this system must include monitoring to determine workers’ exposure to airborne concentration of dust particles.

Section 136 of the Mining and Quarrying Safety and Health Regulation 2001 (PDF, 683KB) requires that relevant Australian or national standards be followed for monitoring or analysis. The relevant standards are shown below. The Coal Mining Safety and Health Regulation 2001 (PDF, 1.2MB) specifies the use of Australian standard AS 2985.

From 1 January 2017, the task of carrying out respirable dust sampling at a coal mine in accordance with AS 2985 will be listed as a prescribed task for section 76(3)(a) of the Coal Mining Safety and Health Act 1999. This means any person carrying out respirable dust sampling at a coal mine in accordance with AS 2985 must have the recognised competencies as determined by the Coal Mining Safety and Health Advisory Committee.

Due to the long latency of many respiratory diseases it is essential that workers’ exposure to dust particles be minimised. Undertaking personal monitoring on a regular basis will facilitate the identification of workers at risk of developing respiratory diseases from occupational sources.

Records of this monitoring must be kept for at least 30 years due to the long latency of many respiratory diseases and their serious health implications.

Standards recommended/required for the measurement of dust in mines

| Fraction being measured | Standard |

|---|---|

| Respirable dust | AS 2985 Workplace atmospheres – method for sampling and gravimetric determination of respirable dust (available from SAI Global) |

| Inhalable dust | AS 3640 Workplace atmospheres – method for sampling and gravimetric determination of inhalable dust (available from SAI Global) |

| Crystalline silica | AS 2985 Workplace atmospheres – method for sampling and gravimetric determination of respirable dust (available from SAI Global) |

| Lead | National standard for the control of inorganic lead at work [NOHSC: 1012] |

| Other airborne dusts | Various |

Introduction to Dust

All respirated dusts must be considered harmful in some degree. Even where there may be only slight danger to the lungs, there is very likely some adverse effect on the respiratory system, particularly to asthmatics or allergy sufferers. Dust particles of size ranging from 0.001 to 0.1 mm (1 to 100 microns) pose a threat to health when they are airborne, reducing visibility, creating an uncomfortable environment (irritation of eyes, ears, nose, throat, skin) and possibly resulting in damage to the tissues of the lungs.

Included among potentially harmful dusts are silica, asbestos, sugar cane fibre, carborundum, diatomite, talc and cotton dust – each of which can produce its own form of lung damage when dust control is inadequate. The most common harmful dust in mines is that which contains silica, and it would appear that the harmfulness increases with the increase in the percentage of silica in the dust. Also, the most harmful dust is that which is less than 5 microns in size, that is, particles smaller than 0.005 mm. As this dust is not visible to the naked eye, it does not follow that because dust cannot be seen there is no danger.

Physiological Effects

When dust-laden air is inhaled, most of the dust particles greater than 5 microns are caught in the mucus which coats the nose, sinuses, trachea and bronchi. They are moved up with the mucus towards the throat and either expectorated or swallowed. Dust particles less than 5 microns can pass into the lungs. Some pass out again with the exhaled air but other particles are caught up in the lung tissue and may eventually result in fibrosis of the lungs. Individual susceptibility seems to play an important part in determining the degree of fibrosis produced. Other factors of importance are the age of the person when first exposed to the dust, the concentration of dust and the years of exposure. Silicosis is lung damage caused by breathing dust containing extremely fine particles of crystalline silica. Crystalline silica is found in materials such as concrete, masonry and rock. When these materials are made into a fine dust and suspended in the air, breathing in these fine particles can produce lung damage. Silicosis can lead to heart failure and increase the risk of other diseases such as tuberculosis. Serious features of silicosis are that it predisposes a person to tuberculoses infection, and that the silicosis may advance even after exposure to harmful dust concentrations has ceased.

Control Methods

This information is a guide to factors that may be required in a dust control strategy and methods that can be used to sample and analyse dust results. Advice on sampling of respirable and inspirable dust is also given in AS 2985 and AS 3640, respectively. Generally, a dust control strategy needs:

1. establishment of a dust control program;

2. monitoring and analyses of airborne dust;

3. implementation of corrective action to control generation of and limit employee exposure to dust, where required; and;

4. results, particularly personal exposure records.

Dust monitoring programs are part of dust control strategies and should be designed to determine and assess concentration of airborne dust for all activities and workplaces. Dust sampling results should be reasonable representations of each person’s exposure to dust. The methods by which dust in working places is suppressed or controlled are universal. They include the following:

- wet drilling, water mist drilling and drilling with an exhaust system to remove and collect dust;

- proper ventilation of working places, particularly dead ends (for example, by supplying dust-free air to the face);

- wetting muck piles when moving broken rock, loading trucks or dumping into bins or stockpiles;

- providing wheels or cutting compound of silicon carbide or aluminum oxide instead of sandstone (to reduce the amount of silica in the dust) and water sprays when using grinding wheels, sawing dimension stone or core cutting;

- use of wetting agents with water in selected processes;

- use of clear water for sprays and mists; and

- use of total wet processes in crushing and screening plants.

Good plant layout practices include:

- separating dusty from non-dusty operations;

- enclosing dusty machines and transfer points and extracting dust through an exhaust system;

- reducing the amount of fall of materials at transfer and discharge points with the discharge chute for fine material being sloped rather than perpendicular;

- using collapsible wind socks (elephant trunks) at the discharge point of stockpile conveyors;

- preventing chutes becoming empty;

- providing a dust-free operator’s room under positive air pressure;

- employing good housekeeping methods by cleaning up spillage, paving the environs of the plant or keeping them oiled or damp;

- reducing the speed of all vehicles near the plant; and

- covering dumps with vegetation as soon as practicable, but in the early stages spraying with chemicals to provide a protective coating.

Pay attention to roads throughout the work site area by:

- providing paved surfaces where practicable;

- watering roads and tracks whether sealed or not;

- restricting vehicles to defined roads or tracks;

- restricting speed of vehicles; and

- watering down loads before leaving the loading site.

Also ensure that any dust produced by blasting in open cut mines and quarries is blown away from neighbouring houses. Remember that too strong an explosive for the rock to be blasted will create excessive dust. While the above considerations are mainly directed towards the elimination of health hazards to employees, it will be apparent that a dust suppression program for surface operations, based on some of the above good practices as are appropriate, will also have the effect of reducing complaints from the community.

Dust Monitoring and Recording

The maximum concentration of dust types including respirable dust, quartz bearing dust and asbestos dust can be obtained from the WORKPLACE EXPOSURE STANDARDS FOR AIRBORNE CONTAMINANTS 2013. Dust can be generated during different stages of operations and therefore workplaces may need to determine personal exposure and what precautions may be required to safeguard employees’ health, and whether a dust control strategy is necessary. Sources of airborne dust include wind action, earth moving, vehicles and moving equipment, drilling, blasting, loading, dumping, feeding, crushing, screening, chutes, conveyors, transfer and discharge points, bins, stockpiles, dumps, loading points and road transport. Dust monitoring programs should ensure a reasonable representation of the dust exposure for given activities and the work site. Programs should be reviewed every two years and appropriate changes made if programs are inadequate for intended purposes.

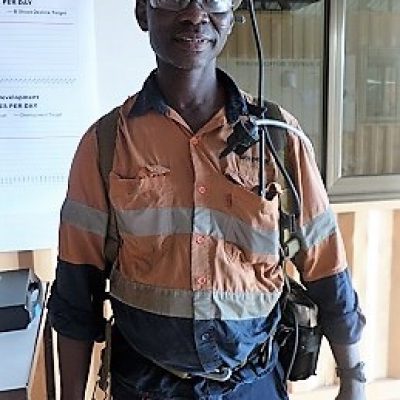

Dust Sampling

Airborne dust samples may be either static or personal. Dust limits are based on personal exposure for a standard shift of eight consecutive hours and calculated as a time-weighted average. The preferred approach is personal dust sampling. Personal dust sampling should:

- identify and quantify airborne dust concentrations a person has been exposed to whilst performing a work activity; and

- if concentration cannot be determined from dust sampling, assume dust originates from the rock being extracted or processed.

Static sampling should:

1. only be performed to verify personal airborne dust results for a particular work area or for engineering purposes;

2. be used to determine air quality by comparison with prescribed limits (such comparisons should be clearly identified in reporting of results); and

3. be more useful than other methods, in areas visited infrequently but where airborne dust poses concern, or impacts on populated work areas.

An adequate number of samples should be taken for all activities to ensure levels of exposure are clearly identified and quantified. Frequent sampling ensures dust exposure levels for an activity are within prescribed limits and exposure trends are adequately identified. Additional sampling is required:

- when flow or quality of air through a work area has changed;

- when processes or activities are modified or new technology introduced; or

- after corrective action has been implemented.

Sampling frequency can be modified:

1. based on trend demonstrated by past results (workplaces with insufficient historical data to delineate trends of airborne dust levels should conduct at least two annual surveys every six months, excluding any follow-up testing after recording unsatisfactory results); and

2. to a higher frequency where ore or mineral contains substances that can generate dust with a high health risk.

The company should carry out personal dust sampling in any area of the site which is known to generate dust. The sampling should take place on a 12 monthly basis in accordance with AS 3580 Methods for Sampling and Analysis of Ambient Air – Determination of Particulates. If the sampling results exceed exposure standards a full investigation of the cause should be undertaken. The aim of the investigation in order of priority should be to:

1. eliminate the source;

2. put in engineered controls; or

3. as a last resort, provide proved appropriate respiratory protective equipment as per AS/NZS 1715 (Selection, Use and Maintenance of Respiratory Protective Devices):

A responsible person should be nominated for this activity.

Concentration of a Type of Dust

Airborne dust in a workplace should not exceed the maximum concentration for the type of dust as specified in the relevant mining, quarrying or levels contained in WORKPLACE EXPOSURE STANDARDS FOR AIRBORNE CONTAMINANTS 2013 published by Worksafe Australia.

Recording Dust Sampling Results

Everyone participating in a dust monitoring program or whose activity was included in a dust monitoring program should be notified of results.

Methods to Determine Concentration of Dusts

The following standards should be used for information on dust sampling procedures and determining concentration levels.

- “Asbestos Code of Practice and Guidance Notes” cat. no. 8928451, AGPS, August 1988.

- Quartz standard A 9950 (Aust 1) obtainable from Australian Safety and Compensation Council

- AS/NZS 2430 Classification of Hazardous Areas

- AS 2985 – 1987, Workplace Atmospheres – Method for Sampling and Gravimetric Determination of Respirable Dust

- AS 2986 – 1987, Workplace Atmospheres – Organic Vapours: Sampling by Solid Adsorption Techniques.

- AS 3640 – 1989, Workplace Atmospheres – Method for Sampling and Gravimetric Determination of Inspirable Dust.

- NOHSC 1003 – 1990, Worksafe National Exposure Standards.

- SAA HB13 – 1992, Electrical Equipment for Hazardous Areas (NEEITCC 181-1:1991).

- WAP 90/012 – 1990, Exposure Standards for Atmospheric Contaminants. WSO 13 – 1994, For the Assessment of Health Risks Arising from the Use of Hazardous Substances in the Workplace.

- WSO 16 – 1991, Exposure Standards for Atmospheric Contaminants in the Occupational Environment: Guidance Notes and National Exposure Standards.

- Worksafe Australia, Guidance Note on the Membrane Filter Method for Estimating Airborne Asbestos Dust

- Worksafe Australia Publication. Asbestos: Code of Practice and Guidance Notes, Cat. no 8928451, AGPS, August 1988.

- ‘Handbook on Quarrying’, Department of Mines and Energy – South Australia

- Silicosis Fact Sheet for Construction for Construction Workers – Canadian Centre for Occupational Safety and Health